Aluminium Plate

Aluminium plates are the result of basic raw-form aluminium being pressed and rolled into panel form under high pressure. An alloy having high mechanical stress, low or high strength but excellent in formability, weldability, and corrosion resistance, high conductibility of electricity and heat.

Product Standard, Specifications and Grade

Series | Description | Feature |

1000 | 1100 representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the aluminium quantity of a maximum number of series. Purity can achieve 99.00% above. | Low strength but excellent in formability and weldability, corrosion resistance, high conductibility of electricity and heat. |

5000 | 5xxx series representatives 5052, 5083. The 5000 series aluminum alloy aluminum belong to the more commonly used series, the main elements for magnesium, with magnesium in the amount between 3-5%. And can be called aluminum magnesium alloy. Key features for low density, high tensile strength, elongation rate is high. In the same area under the weight of the magnesium alloy aluminum less than other series. | Excellent corrosion resistance and weld ability together with easy to process and weld and superior hardness & heatproof can be anodized for increased corrosion resistance |

6000 | 6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications. | Easy to process, good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

7000 | 7000 aluminum alloy is another common alloy, wide variety. It contains zinc and magnesium. The best strength in the common aluminum alloy is 7075 alloy, but it can’t be welded, and its corrosion resistance is rather poor, many manufacturing parts with CNC cutting is 7075 alloy. | 7000 series is high tensile to process with special alloy |

Chemical Composition % |

Alloy No. | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | V | Ti | Zr | Al |

1100 | 0.45 | 0.35 | 0.05-0.20 | 0.03 | – | – | – | 0.01 | 0.05 | – | – | Remainder |

5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | – | 0.1 | – | – | – | Remainder |

5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | – | 0.25 | – | 0.15 | – | Remainder |

6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | – | 0.25 | – | 0.15 | – | Remainder |

6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.90 | 0.1 | – | 0.1 | – | 0.1 | – | Remainder |

7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | – | 5.1-6.1 | – | 0.2 | – | Remainder |

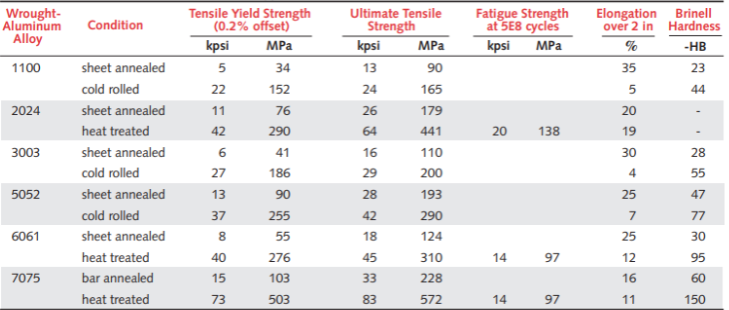

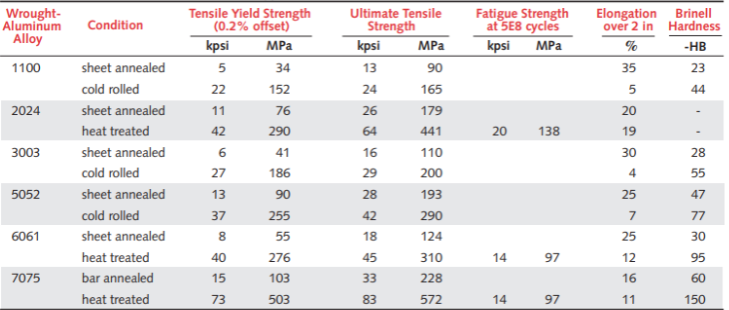

Mechanical Properties

Surface Finish

It is a light weight silvery white metal which is ductile and soft.

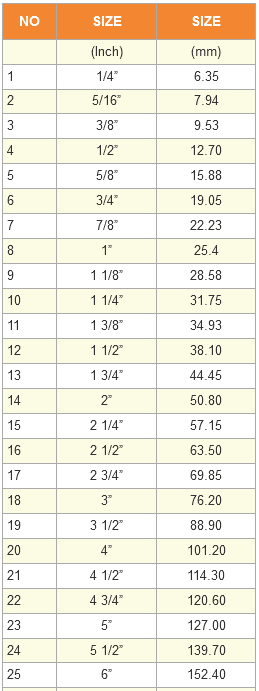

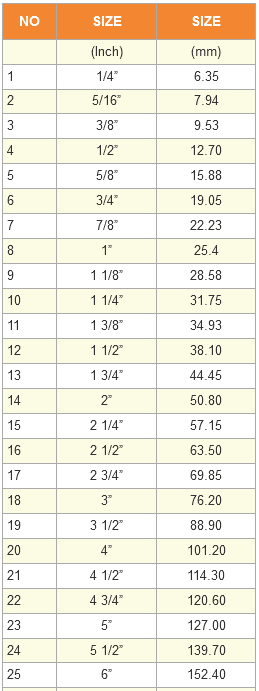

Size Range

Thickness : 0.3mm – 127mm Width : 4FT, 5FT

Length : Standard is 8ft or 10ft but customize size is available.

Products Application

- Building and Infrastructure Engineering

- Aerospace and Automotive

- Electrical Appliances

- Cookware and kitchen utensil

- Vessel

- Printing and Advertising Boards

- Precision Parts

- Injection Mould

- Electronic Components

Aluminium Flatbar

Aluminum Flat Bars are available in a wide variety of sizes. Aluminum alloy has lightweight, excellent electrical conductivity, and high corrosion resistance, which makes it a good material for applications in medical assembly, aircraft construction, and structural and electrical components.

Grade: 6061 / 6063

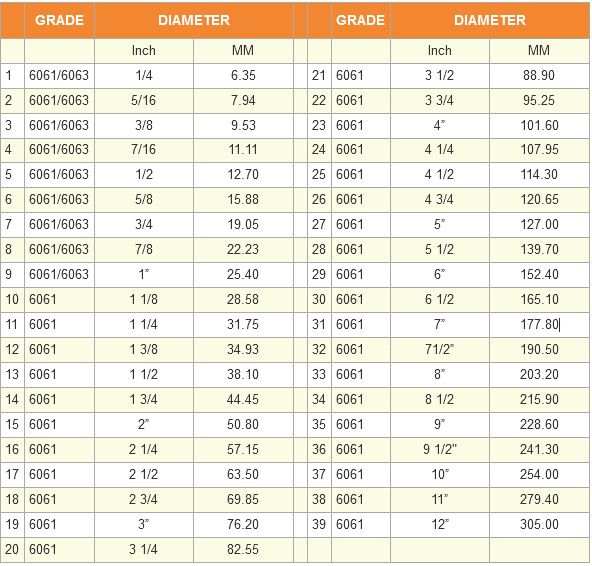

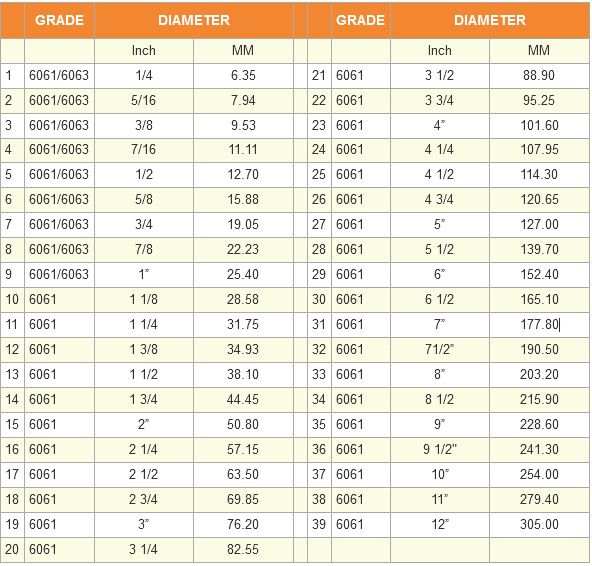

Aluminium Round Bar

Aluminium round bar are an essential component in many industrial applications. It is corrosion-resistant, water proof, rustproof. It works very well in low temperatures and retains its toughness and hardness. Aluminium round bar are also used on food processing units, heat exchangers, and other similar industrial applications. It is being more thermal conducive than steel, the aluminium products can be used in both cooling and heating applications. Its nontoxic properties, the metal is extensively used in the manufacture of several cooking utensils and appliances.

Grade: 6061 / 6063

Aluminium Angle Bar

Aluminum angles consist of two legs which is the types of equal or unequal lengths and arranged to form a 90 degree angle. Because of the material strength and lightweight construction, these components are suitable for use in structural and general engineering and manufacturing applications across a wide range of industries, including building, construction, and transportation.

Grade:6061 / 6063

Aluminium Square Bar

Aluminium square bar are an essential component in many industrial applications. It is corrosion-resistant, water proof, rustproof. It works very well in low temperatures and retains its toughness and hardness. Aluminium square bar are also used on food processing units, heat exchangers, and other similar industrial applications. It is being more thermal conducive than steel, the aluminium products can be used in both cooling and heating applications. Its nontoxic properties, the metal is extensively used in the manufacture of several cooking utensils and appliances.

Grade: 6061

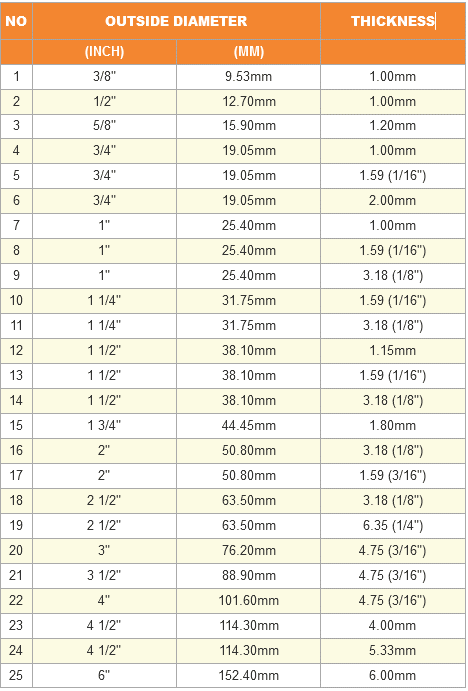

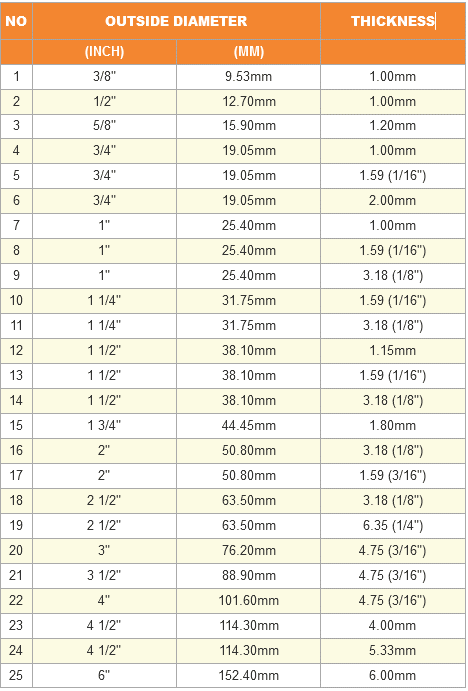

Aluminium Tubes

Aluminium tubes are an essential component in many industrial applications. It is corrosion-resistant, water proof, rustproof. It works very well in low temperatures and retains its toughness and hardness. It is being more thermal conducive than steel, the aluminium products can be used in both cooling and heating applications. Because of the material strength and lightweight construction, these components are suitable for use in structural and general engineering and manufacturing applications across a wide range of industries, including building, construction, and transportation.

Grade: 6061 / 6063

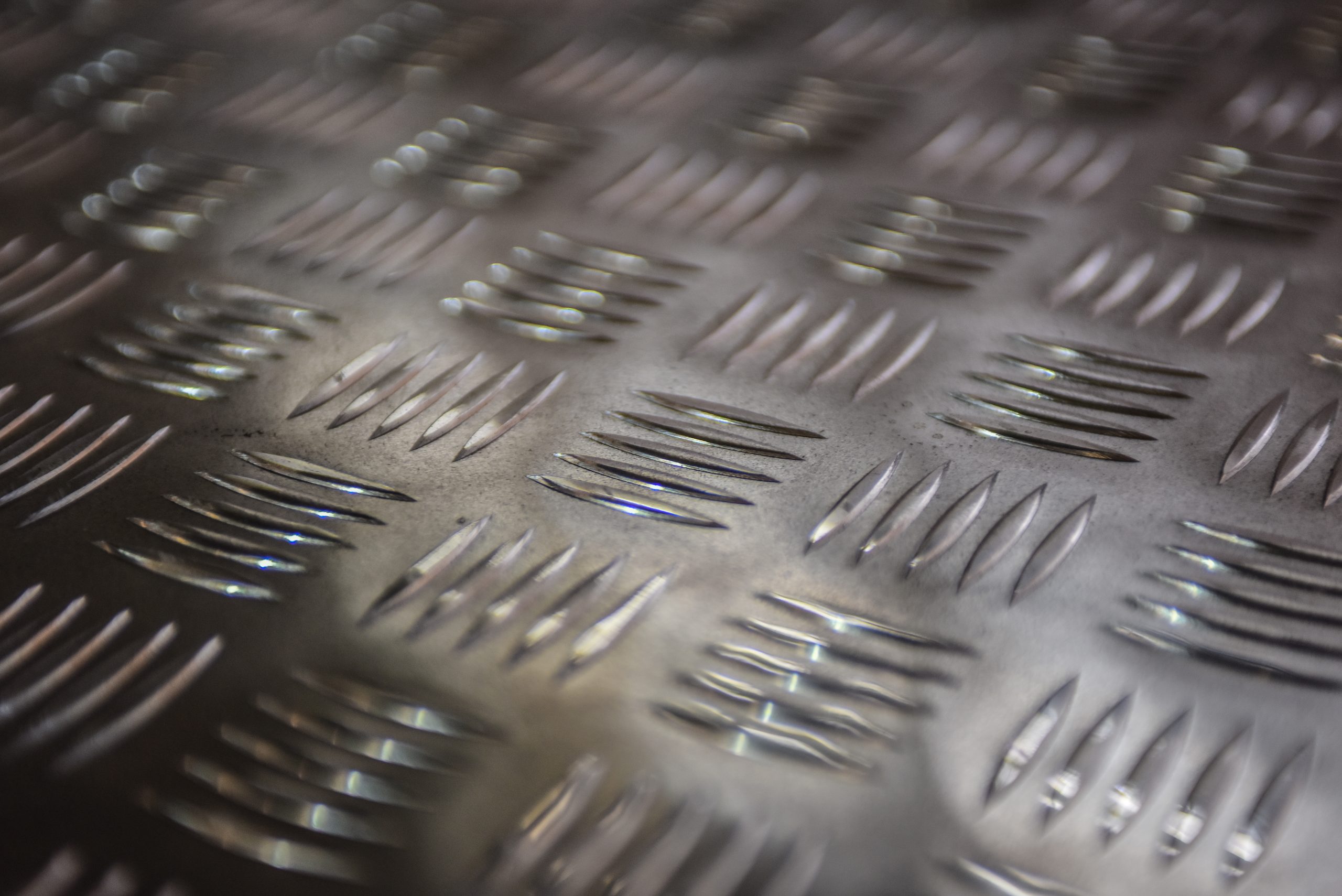

Aluminium Chequered / Tread Plate

Aluminum chequered / tread plate is widely used in decorative, shipbuilding and architectural applications. Having good forming, drilling and welding ability, Its raised diamond lug pattern provides good slip resistance.

Grade: AA 1100 H14

Size: 1.5MM – 6.0mm Width: 4ft x 8ft / 4ft x 12ft

NO | DIMENSION | WEIGHT PER SHEET (KG) |

1 | 1.5MM X 1219MM X 2438MM | 12.98 |

2 | 2.0MM X 1219MM X 2438MM | 17.31 |

3 | 2.5MM X 1219MM X 2438MM | 21.64 |

4 | 3.0MM X 1219MM X 2438MM | 25.97 |

5 | 4.0MM X 1219MM X 2438MM | 34.62 |

6 | 4.5MM X 1219MM X 2438MM | 38.95 |

7 | 5.0MM X 1219MM X 2438MM | 43.28 |

8 | 6.0MM X 1219MM X 2438MM | 51.94 |